Transformer design is an important subject in electrical engineering because it enables the transformers to work effectively, securely, and stably in their intended use. Right from power generation, distribution to industrial application, design factors of transformers play a vital role. This article explores the important aspects in shape and size of transformers with the materials of construction, core construction, cooling, insulation, etc.

Introduction

Transformers: Electrical Networks are the backbone in most electrical, electronic appliances and which are used in domestic, industrial, commercial and other sectors.

Electrical transformers are crucial apparatus in electrical circuits since they help in converting electricity from one circuit to another. There they regulate the power and voltage up to areas that are very vital in supporting the electrical networks. A general overview of the transformer design is important to ensure these systems are efficient and reliable.

Types of Transformers

Power Transformer

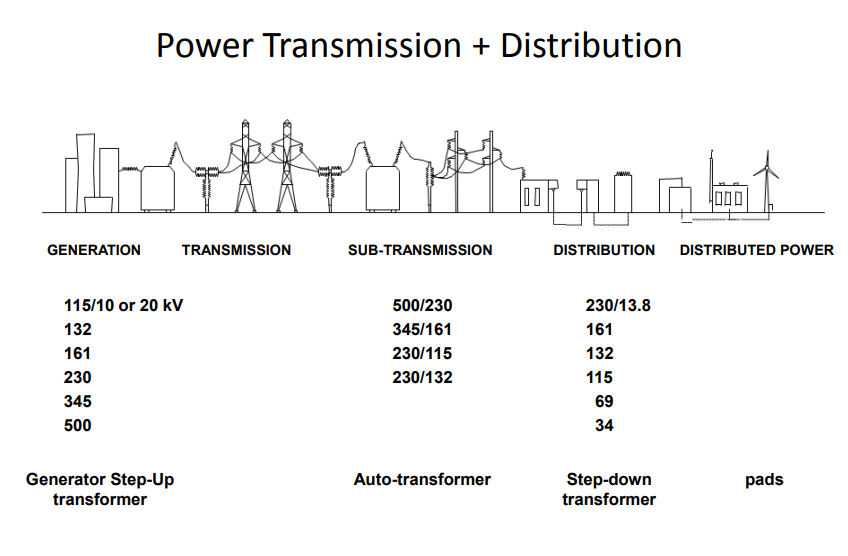

Considering the transmission networks, power transformers are employed for the purposes of either increasing or decreasing electromagnetic potentials. They are for right efficiency performance and Enhanced Parameters are of immense value with reference to the losses which take place while transmitting electricity over a large distance.

Distribution Transformer

The distribution transformers are employed in the distribution system; and offer the final step of voltage transformation of the electrical network. They transformed the voltage used in the transmission line to one suitable to the consumers.

Isolation Transformers

Another type of transformer is the isolation transformer which is used in the electrical isolation of circuits through limiting of the noises. They are used in sensitive zones, when the shield of the devices against electrical interferences is mandatory.

3-Phase Transformer – Construction & Working Principle explains types of transformers in more detail.

Applicable Standards

Standards in transformer design ensure that products meet specific safety, performance and reliability criteria. They provide benchmarks for quality and facilitate compatibility and interoperability across different systems and sectors.

Several organisations develop and publish standards for transformers, including the Institute of Electrical and Electronics Engineers (IEEE), the International Electrotechnical Commission (IEC), the National Electrical Manufacturers Association (NEMA), British Standards (BS), and the American National Standards Institute (ANSI).

IEEE Standards

The IEEE C57 series is one of the most comprehensive standards for transformers, covering various aspects of design, testing and performance. Visit IEEE website to understand IEEE C57

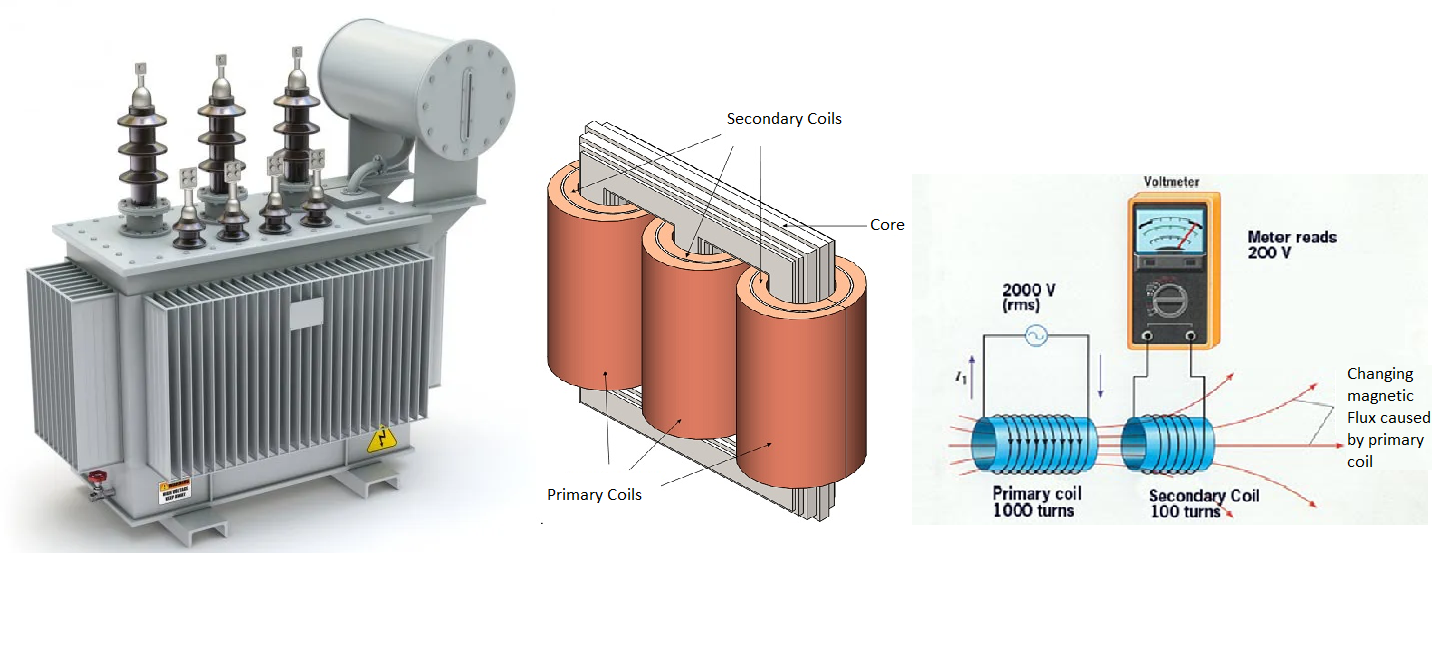

IEC Standards

The IEC 60076 series is a globally recognised set of standards for power transformers. Visit IEC website to understand IEC 60076 standard.

NEMA Standards

NEMA publishes standards that address various aspects of transformer design and application and ensure compatibility with the broader electrical infrastructure. Visit NEMA website to understand NEMA standard.

ANSI Standards

The ANSI C57 series provides standards for various types of transformers, including distribution, power, and regulation transformers. Visit ANSI website to understand ANSI C57 standard.

British Standards (BS)

BS 171 specifies requirements for power transformers, including design, manufacture and testing procedures. This ensures that transformers meet British safety and performance standards.

BS EN 60076 is aligned with IEC 60076, providing a harmonised standard for power transformers in the EU and UK.

CSA Standards

The Canadian Standards Association (CSA) provides standards for transformers used in Canada, ensuring safety, performance and regulatory compliance.

Design Consideration

Core Design

Core Materials

Core size

The shape of the core, whether it is E-core, U-core or toroidal, affects the magnetic flux distribution and overall performance. Each design has its applications depending on the required performance characteristics.

Magnetic flux

Magnetic flux considerations are essential to minimize core losses and ensure efficient operation. Proper core design helps manage magnetic flux to minimize hysteresis and eddy current losses.

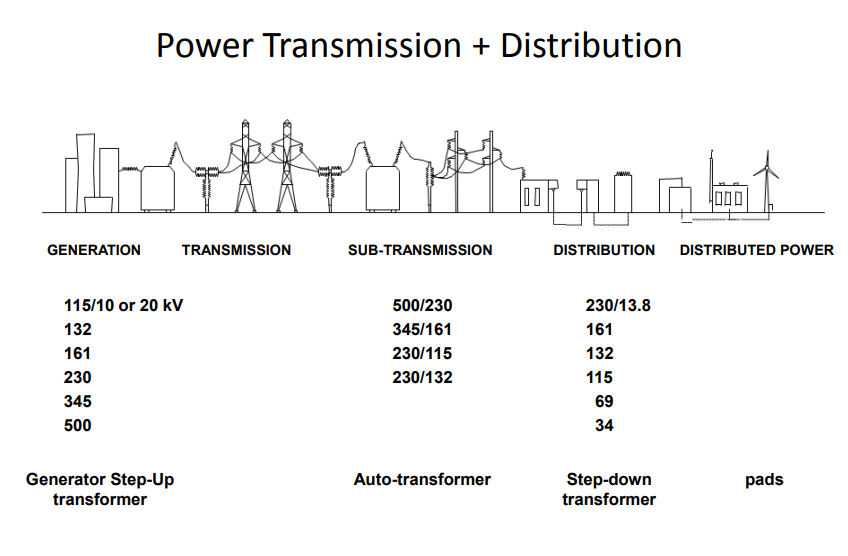

Winding Design

Conductor Materials

Winding Techniques

Various winding techniques, such as helical, disc, and foil windings, are used to optimise the performance of transformers. Each technique offers different benefits in terms of reducing losses and improving heat dissipation.

Leak response

Leakage reactance affects voltage regulation and short-circuit performance of transformers. Proper winding design helps reduce leakage reaction to improve overall performance.

Cooling Methods

Oil cooling

Air Cooling

Air cooling, or natural ventilation, relies on the circulation of air around the transformer to dissipate heat. It is commonly used in smaller transformers and where environmental conditions allow for effective cooling.

Forced Cooling

Forced cooling techniques, such as forced air or forced oil circulation, enhance heat dissipation by actively moving the cooling medium. These methods are employed in high-power transformers to maintain optimal operating temperatures.

Insulation Systems

Insulation Materials

The choice of insulation materials, such as paper, resin, and synthetic polymers, affects the dielectric strength and thermal stability of transformers. High-quality insulation is essential for long-term reliability and safety.

Dielectric Strength

Dielectric strength is a measure of an insulation material’s ability to withstand electric stress without breakdown. Ensuring adequate dielectric strength is critical in preventing insulation failure and maintaining transformer performance.

Insulation Classes

Insulation classes, defined by temperature ratings, determine the maximum operating temperatures for transformer components. Choosing the appropriate insulation class is vital for ensuring longevity and performance under varying load conditions.

Voltage Regulation

Voltage Drops

Voltage drops in transformers can impact the performance of electrical systems. Understanding and managing voltage drops through proper design and regulation methods is essential for maintaining stable operation.

Regulation Methods

Various methods, such as tap changers and voltage regulators, are used to maintain consistent voltage levels. These methods help in adjusting the transformer’s output to match load requirements and minimize fluctuations.

Impact on Performance

Voltage regulation directly influences the efficiency and reliability of transformers. Proper design and implementation of regulation techniques ensure optimal performance under different operating conditions.

Load Handling

Load Types

Transformers are designed to handle various load types, including resistive, inductive, and capacitive loads. Each load type presents unique challenges that must be addressed in the design phase.

Load Variability

Load variability, such as peak and off-peak periods, affects transformer performance. Designing transformers to accommodate these variations ensures consistent and reliable operation.

Load Management

Effective load management involves balancing the load distribution and preventing overload conditions. Proper load management strategies enhance transformer lifespan and reduce the risk of failures.

Losses in Transformers

Core Losses

Core losses, or iron losses, occur due to the alternating magnetic field in the transformer’s core. These losses are influenced by the core material and design, and minimizing them is crucial for improving efficiency.

Copper Losses

Copper losses, or I²R losses, result from the resistance of the windings. These losses can be reduced by optimizing conductor materials and winding techniques.

Stray Losses

Stray losses are caused by leakage flux that induces currents in non-winding components. Proper transformer design helps in minimizing stray losses to enhance overall efficiency.

Efficiency Improvement

Loss Minimization

Minimizing losses through advanced materials, design techniques, and manufacturing processes is essential for improving transformer efficiency. Each design aspect plays a role in reducing losses and enhancing performance.

Design Techniques

Innovative design techniques, such as optimizing core geometry and using high-efficiency winding configurations, contribute to better performance. Continuous research and development in design methods drive efficiency improvements.

Material Choices

Selecting high-quality materials for cores, conductors, and insulation significantly impacts transformer efficiency. Advances in material science provide new opportunities for enhancing performance and reducing losses

Thermal Management

Heat Dissipation

Effective heat dissipation is crucial for preventing thermal overload and ensuring reliable operation. Various cooling methods and thermal management strategies help in maintaining optimal temperatures.

Thermal Runaway Prevention

Thermal runaway, a condition where excessive heat leads to further heating, must be prevented to avoid catastrophic failures. Proper design and monitoring are essential in managing thermal conditions.

Temperature Monitoring

Continuous temperature monitoring provides real-time insights into transformer performance and helps in early detection of potential issues. Advanced sensors and monitoring systems play a critical role in thermal management.

Magnetic Considerations

Magnetic Saturation

Magnetic saturation occurs when the core material reaches its maximum magnetic flux capacity, leading to increased losses. Designing transformers to avoid saturation is essential for efficient operation.

Hysteresis

Hysteresis losses result from the lagging behavior of magnetic domains in the core material. Reducing hysteresis through material selection and core design enhances transformer efficiency.

Eddy Currents

Eddy currents are induced currents in the core that cause additional losses. Laminating the core and using high-resistivity materials help in minimizing eddy currents losses

FAQs

Q1 What are the key parameters in transformer design?

Key parameters include core material, winding design, cooling methods, insulation systems, and voltage regulation.

Q2 How do cooling methods impact transformer performance?

Cooling methods affect heat dissipation and thermal management, influencing overall efficiency and reliability.

Q3 Why is insulation important in transformers?

Insulation ensures dielectric strength and thermal stability, preventing electrical breakdown and enhancing safety.

Q4 What role do standards and regulations play in transformer design?

Standards and regulations ensure that transformers meet safety, performance, and environmental requirements, promoting reliability and market acceptance.

Q5 How can transformer efficiency be improved?

Efficiency can be improved by minimizing losses, optimizing design techniques, and selecting high-quality materials.

Q6 What are smart transformers?

Smart transformers are equipped with digital sensors and communication capabilities, offering advanced monitoring and control for improved performance and reliability.